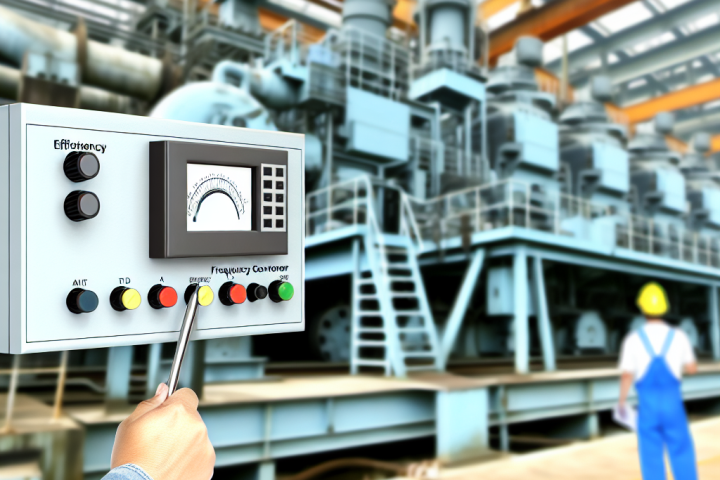

Frequency converters are essential tools in modern industrial applications, offering precise control over the speed and torque of electric motors. These devices play a critical role in enhancing the efficiency and performance of various machines and processes. By converting the frequency of the power supplied to motors, frequency converters allow for seamless speed adjustments, leading to significant energy savings and reduced mechanical stress. To get a better understanding of how frequency converters work and their benefits, watch this informative video:

.Applications and Advantages of Using Frequency Converters

Frequency converters are particularly useful in industries where machinery must operate at different speeds for various tasks. For example, in the food and beverage industry, production lines typically require different speeds to handle and package products delicately and efficiently. Frequency converters adjust the motor’s speed in real time to match the production demands, hence optimizing the whole production line for speed and reducing waste.

Moreover, the ability to control the motor speed not only preserves the life of the motor by reducing wear and tear but also diminishes the energy consumption significantly. This is particularly important in large-scale industrial setups where long-term operational costs can be drastically cut down through the optimized use of energy. Companies like VYBO Electric provide advanced frequency converter solutions that push the boundaries of what is possible in terms of electrical motor efficiency and operational flexibility. These advancements support a more sustainable and cost-effective industrial environment.

Frequency converters continue to evolve, incorporating smarter technology and more robust designs to handle a wide range of industrial challenges. This ongoing advancement is pivotal in industrial sectors aiming to improve sustainability while keeping up with the increasing demand for higher efficiency and innovative technology solutions.